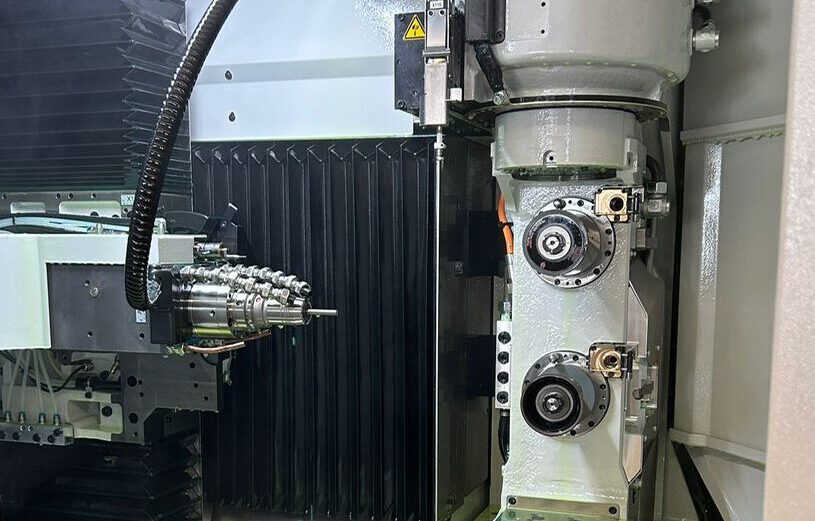

We are installing the latest and most efficient Hybrid machine right now.

The new V Hybrid 260 is a state-of-the-art machine with

eroding and grinding functions. In addition to an automatic

workpiece changer, the machine has an eroding wheel

and grinding wheel changer, which enables to unmanned 24/7 production.