With the Vollmer V Hybrid, we have added another high end machine to

our workshop.

With the Vollmer V Hybrid, we have added another high end machine to

our workshop.

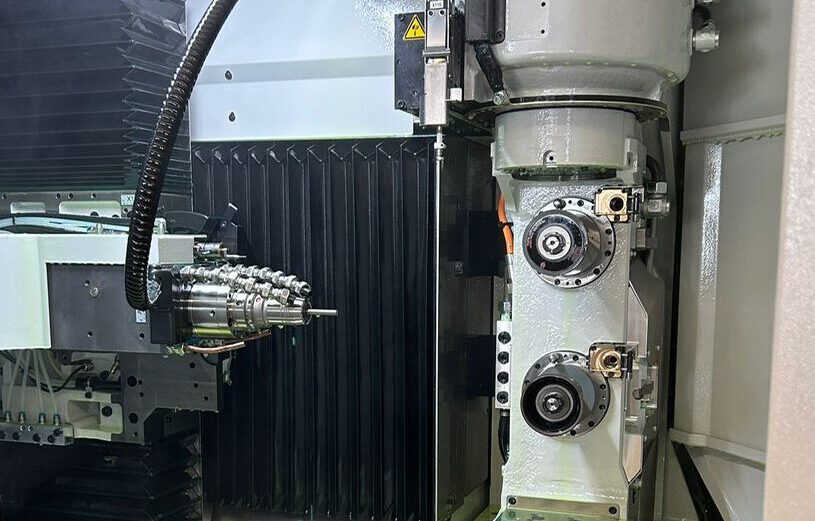

In order to further automate our tool body production, we have

invested in a 5-axis machine with pallet pool. This means we are

well equipped for 24/7 operation.

We are installing the latest and most efficient Hybrid machine right now.

The new V Hybrid 260 is a state-of-the-art machine with

eroding and grinding functions. In addition to an automatic

workpiece changer, the machine has an eroding wheel

and grinding wheel changer, which enables to unmanned 24/7 production.

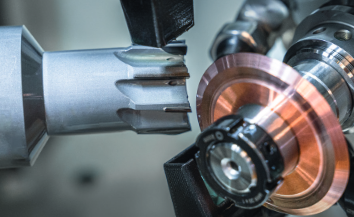

This unique PCD tool is for machining of pistons. It enables to run

higher feed rates and despite its staggered PCD-cutting edge design

the surface finish is flawless.